The concept involves a high-temperature internal combustion engine that operates on water, split into hydrogen and oxygen through electrolysis. This system uses an electrolyzer powered by a small nuclear reactor to separate water into hydrogen and oxygen gases. The small nuclear reactor provides a consistent and robust source of electricity for the electrolysis process, ensuring a steady production of hydrogen and oxygen.

Once separated, the hydrogen and oxygen gases are stored in high-pressure tanks equipped with safety features to prevent leaks and control pressure. The engine is designed to withstand the high temperatures and pressures generated from the combustion of hydrogen and oxygen. In the combustion chamber, these gases are mixed and ignited, producing high temperatures and water vapor as a byproduct. This reaction generates energy that is converted into mechanical power to drive the engine’s pistons or turbine, or it can be used to generate electricity, potentially creating a self-sustaining loop if the electricity is fed back into the electrolyzer.

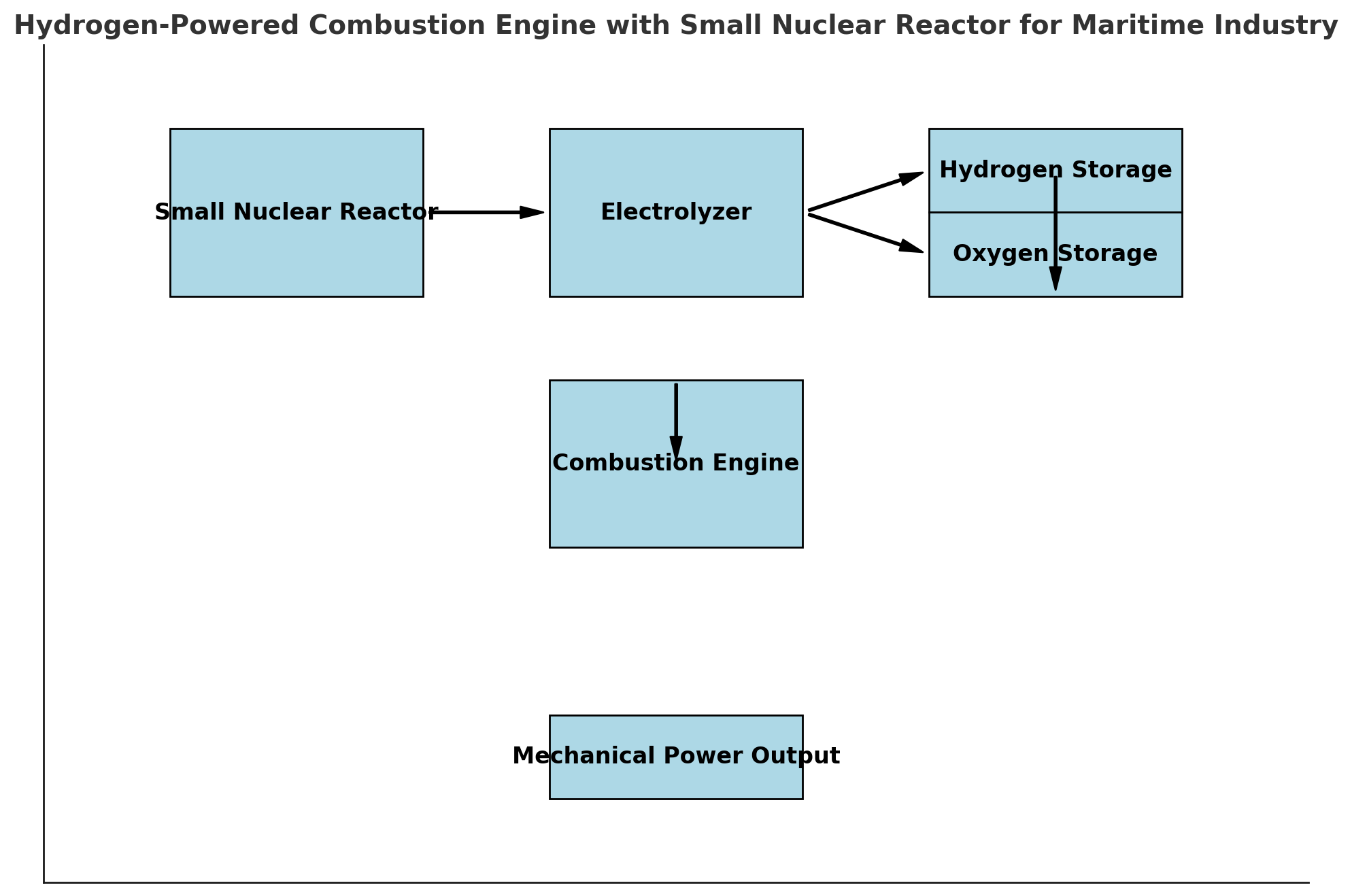

Here is a diagram illustrating the concept of a hydrogen-powered combustion engine combined with a small nuclear reactor for the maritime industry:

Small Nuclear Reactor: Provides a consistent and robust source of electricity for the electrolysis process.

Electrolyzer: Uses electricity from the nuclear reactor to split water into hydrogen and oxygen.

Hydrogen Storage: Stores the hydrogen gas produced by the electrolyzer.

Oxygen Storage: Stores the oxygen gas produced by the electrolyzer.

Combustion Engine: Combines hydrogen and oxygen to generate high temperatures and mechanical power.

Mechanical Power Output: Converts the energy generated by the combustion engine into mechanical power for the ship.

The arrows indicate the flow of materials and energy through the system, showing how the small nuclear reactor powers the electrolysis process, leading to the storage and subsequent combustion of hydrogen and oxygen to produce mechanical power.

The primary emission from this process is water vapor, making it an environmentally friendly technology with no harmful pollutants. The inclusion of a small nuclear reactor addresses one of the main challenges of hydrogen production: the energy-intensive nature of electrolysis. By using nuclear power, the system gains a highly efficient and low-emission energy source, which is crucial for the viability of this concept.

In the maritime industry, this technology offers significant benefits. Ships powered by this system would produce zero emissions, drastically reducing the environmental impact of maritime transport. The small nuclear reactor ensures a reliable energy supply for long voyages, eliminating the dependency on fossil fuels. Additionally, the use of nuclear energy for electrolysis aligns with global efforts to transition to cleaner energy sources and can provide the necessary power for large-scale hydrogen production.

The feasibility of this concept depends on advancements in several areas, including the efficiency of electrolysis, the durability of engine materials, and comprehensive safety measures for handling and storing hydrogen and oxygen gases. Furthermore, integrating a small nuclear reactor into maritime vessels requires addressing regulatory, safety, and public acceptance challenges.

In summary, combining hydrogen-powered combustion engines with small nuclear reactors presents a promising and sustainable solution for the maritime industry. This innovative approach can lead to significant reductions in emissions and reliance on fossil fuels, paving the way for a cleaner and more sustainable future in maritime transport.

Leave a Reply